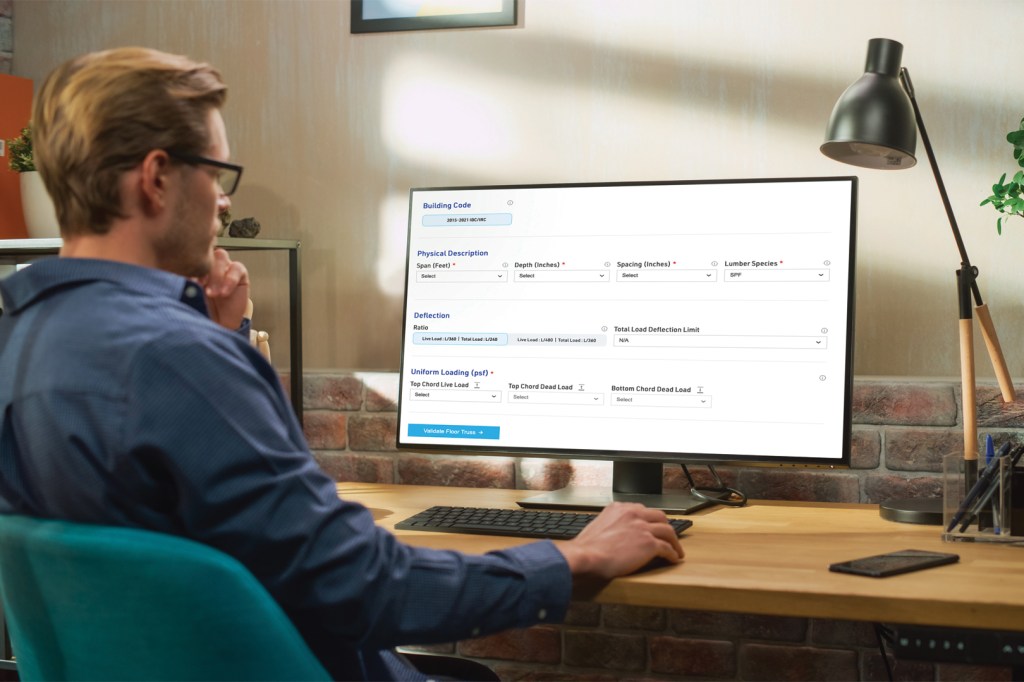

Floor Trusses

Resource Materials for Open Web

Explore the unique advantages of floor truss systems over traditional floors through our collection of frequently asked questions, downloadable articles, and webinar content.

Webinar Feature: Myths vs. Facts

In this recorded webinar, Joseph Murphy, Senior Director of Business Development, and Stephen Keller, Director of Design Engagement at MiTek, discuss common misconceptions that can hinder builders from using Open Web Floor Trusses.

Watch to see how they address concerns and feedback they’ve received related to costs, safety, and more.

Joe Murphy

Sr. Director, Homebuilding Consulting & Education

Stephen Keller, P.E.

Director, Design Engagement

Key Takeaways

Design floors

for the building

not the other

way around

Prioritize

total costs

over product

piece costs

Collaborative

design

maximizes

value for all

More OWFT Articles

Email our Design Engagement team at designengagement@mii.com for questions or to receive more information.